Machinery

With more than 30 years of mechanical manufacturing experience,

Hankook Engineering Works engineers and manufactures facilities for tire manufacturing

with the latest high technology and in a wide variety of industries.

Optimized

Engineering Consulting and

Customized Facilities

Based on our engineering experience and know-hows from Hankook Tire & Technology plants in both Korea and overseas locations, we are equipped with qualified performance and technologies for each processing phase, such as beading, cutting, building, curing, inspection, and testing. Each facility is professionally operated and supervised by our Masters and Supervisors with extensive knowledge in the field. With Hankook Engineering Works, you can experience optimized engineering consulting and facilities that are individually customized for your business.

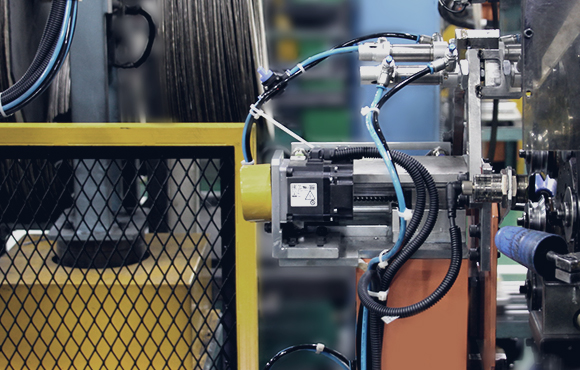

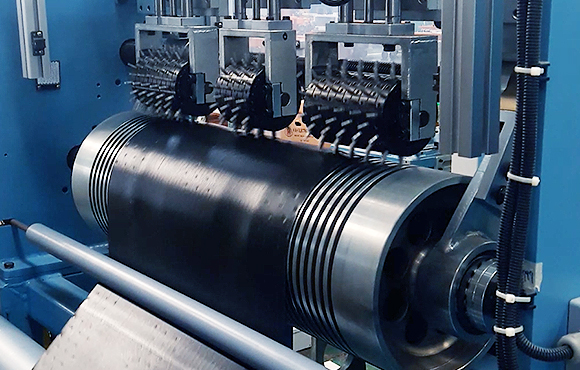

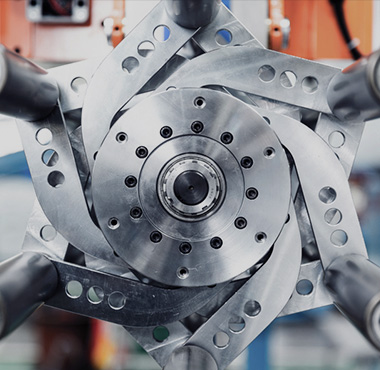

01Bead

With an independent bead production plant and accumulated know-hows in the field, Hankook Engineering Works provides optimal solutions for quality and work efficiency. Experience the latest bead facilities, fully implemented with the Fool Proof system and the Auto Setting system.

Our bead facilities effectively reduces in-factory workload with the Auto Setting system while providing a safe working environment and the best productivity through the Fool Proof system. Based on the accumulated know-hows from our independent bead manufacturing plant, we offer a flexible combination of facilities with the best loading-unloading system that satisfies each and every customer’s needs. For any issues in facility operation or products of various specifications, we provide individualized, optimal solutions by installing the best facilities for improved efficiency, productivity, and quality.

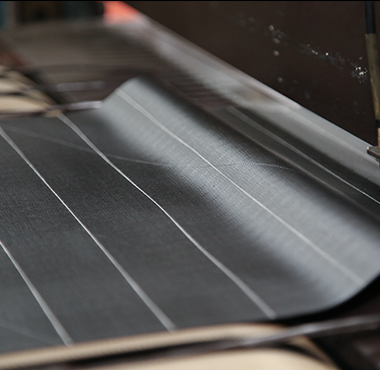

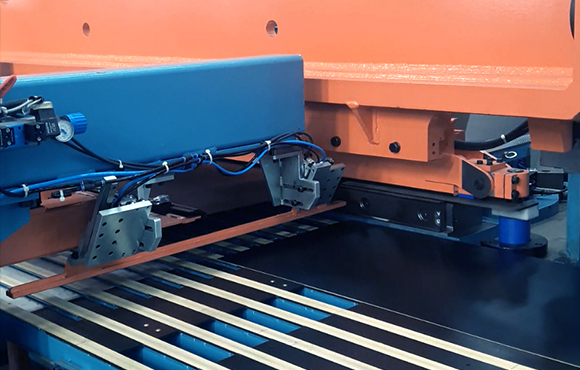

02Cutting

At Hankook Engineering Works, we provide manufacturing facilities with facilities that are optimized for different types of material. Cutters of Guillotine Type and Rotary Type are manufactured depending on the shape of the blades for PCR/LTR/TBR tires, offering a variety of high-performance and high-quality customizations. Our cutters ensure accurate and standardized cross-sectional quality as well as optimal speed control to add reliability to the tire manufacturing process.

Cutting steel or textile topping cord sheets at a constant width and angle, joining and winding them to the liner based on our advanced technologies and our know-hows in manufacturing, we provide an optimal system that satisfies both the latest trend and customer needs. We also offer the finest facilities with optimized space utilization and work efficiency, productivity, and quality.

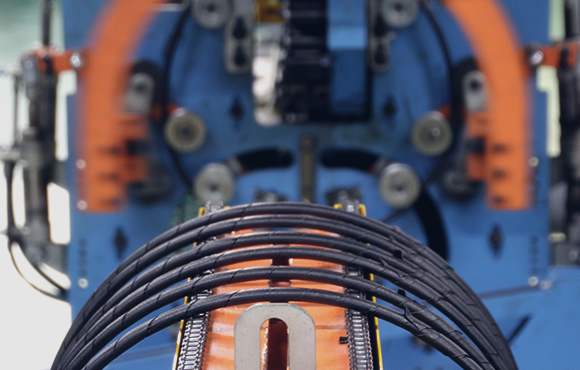

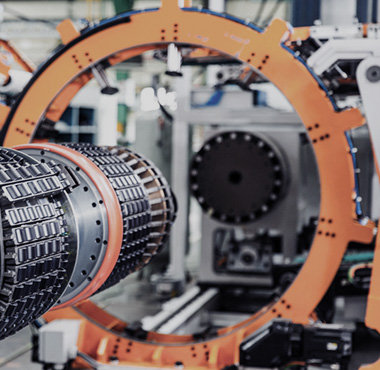

03Building

With exceptional productivity and flexibility in tire building process, we provide a variety of high-performance and high-quality customizations, such as tire manufacturing processes, facility configurations, and know-hows for various materials. MES linkage, self-checking/feedback system, and other various options are available for you.

Its safety design ensures the safety of workers first, and above all, we have the world’s best technology and know-hows on facility maintenance.

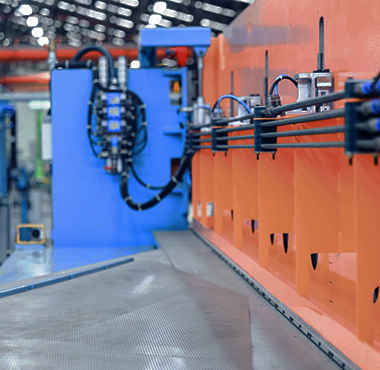

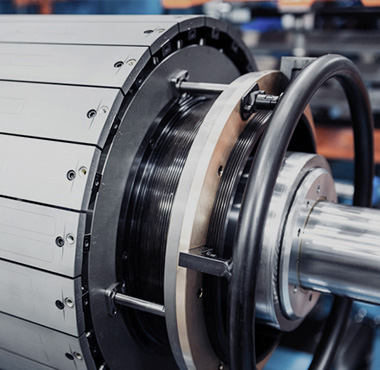

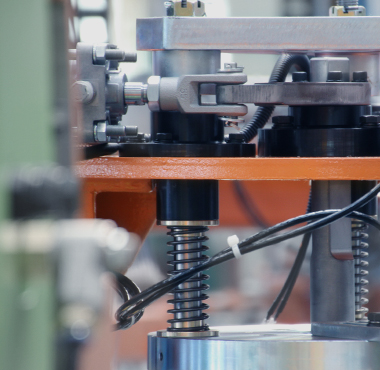

04Curing

Vulcanizing machines produced at Hankook Engineering Works combine excellent durability and high productivity that produce various sizes of tires, including PCR and TBR, and exports proven facilities to US, Indonesia, Hungary, and China.

From Frame Type and Column Type to PCR/TBR, 47" to 65”, and other specifications, we provide various customizations and PCI for the needs of our customers.

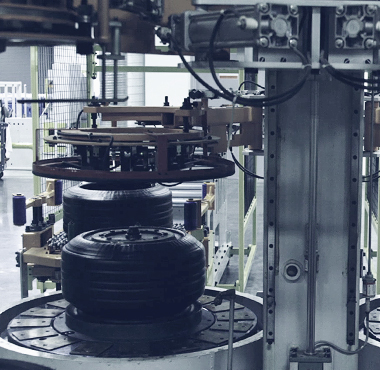

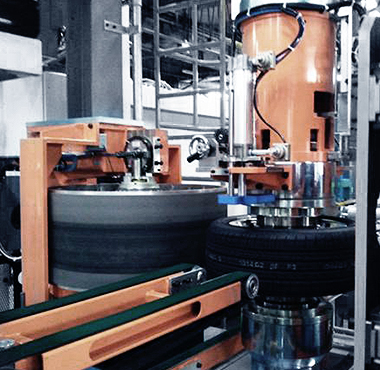

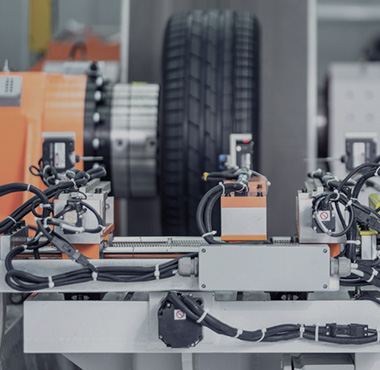

05Inspection

Inspection facility is an important facility for inspecting the exterior condition and performance quality of the finished tire. Hankook Engineering Works produces world-class performance-inspection facilities.

Hankook Engineering Works features inspection facilities of Uniformity and Dynamic Balance that comply with ISO test regulations. Our high-speed and high-precision facilities will greatly contribute to the improvement of our customer’s productivity. Facility customization is also available to meet various needs, such as run-out measurement or rim replacement, of our customers.

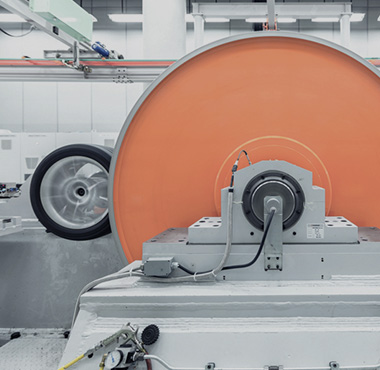

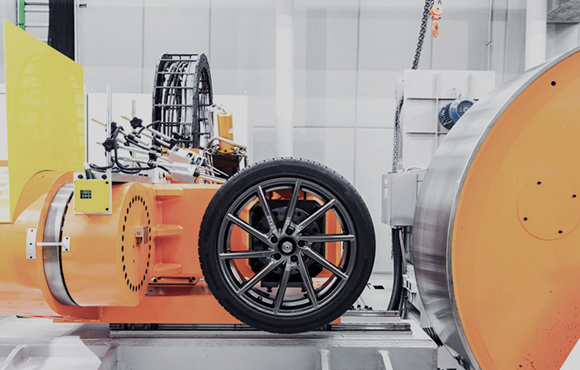

06Test

Testing facility checks for the performance, quality, and safety of tires that are finished or being developed.

The quality of our testing facilities in terms of precision, repeatability, and durability is among the best in the world, and our facilities are used for performance evaluation of R&D in both Korea and overseas tire plants as well as at independent. testing institutions.

Our tire durability testing facilities have a range of line-up features that conform to the regulations for ISO (International Organization for Standards), and can conduct tests for all standards from PCR to TBR tires. Featuring various and conditions, such as slipping or creating a camber, our facilities are used for testing tires at high-speed, high-load, and for long-term. Rapid acceleration and deceleration functions are also available for testing characteristics and durability of F1 and premium OE tires. Hankook Engineering Works has developed a rolling resistance facility that measure tire rotational resistance and other testing facilities such as Plunger & Bead Unseat Machine, Electric Resistance Test Machine, and Dimension Measuring Equipment, which are essential and mandatory facilities by law, and are operating such facilities in plants both in Korea and overseas.

Our rubber-block friction evaluation facility is developed to study the frictions property of tires under dry and wet driving conditions using various surface such as asphalt and concrete. It can create different road conditions in indoor-laboratories from snowy to ice-covered roads regardless of the season, and allows friction testing under intense conditions at -20 ºC. Linked with the real-car testing, this facility is used in various ways for researching and developing high-performance tires.

- Industrial Machinery

Our experts offer a full range of Total Service from facility design, manufacturing, and test runs across the industry.

Learn more